In recent years, the gasket sector has drastically changed. Both economically and technologically, CNC gasket cutting machines are far superior to traditional methods used to cut gaskets, like die cutting. Hold old and new machines side by side, and the difference is clear. A cnc gasket cutting machine outperforms the old machines in all aspects: speed, savings, costs, and the reduction of material leftover after cutting. Using CNC machines is far superior to cutting by a die and traditional methods. Both CNC and die cutting methods achieve similar results. However, CNC accuracy and flexibility are unmatched.

Precision Beyond Traditional Methods

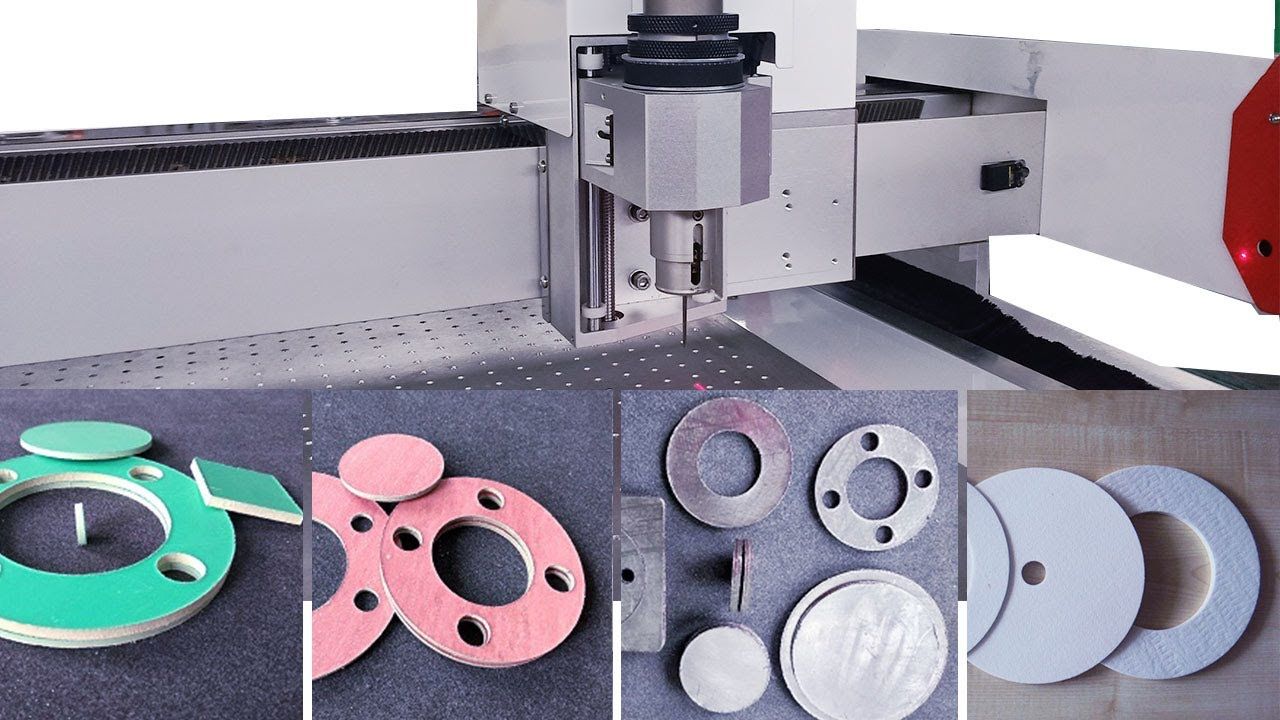

CNC machines truly take innovation to new heights. The traditional method of cutting gaskets and other materials relied on cutouts in die blocks. CNC machines are programmed to cut materials at a precise point. A die block can only achieve rough cuts, as CNC machines are shown to cut far more detailed and precise. An added benefit, CNC machines cut complex and irregular gaskets flawlessly. Traditional methods using CNC machines are much older and thus far less machine-friendly than current methods. Adding a die to the CNC method only harms the precision and accuracy is unheard of.

Elimination of Tooling Costs

Every gasket design comes with a unique shape that needs a custom-made mold, and that means each new shape comes at a cost and involves a considerable amount of time and money. Not to mention the space it would take to store them, any business that needs to produce numerous types of gaskets would easily find these expenses mounting up time and time again. Tooling costs as a whole can be eliminated with the use of CNC gasket cutting machines, as they can separate the design from the molds digitally and eliminate the need for a physical mold. Not having a physical mold also means having an instant means of production, further cutting costs around the apparatus. CNC also allowed for a dramatic reduction in production time, as the CNC can base itself on designs that vary according to each unique customer, bringing in more clients.

Faster Production and Reduced Lead Times

In the case of gaskets that are custom-made, the gaskets are likely to take a long period of time and considerable effort to make. Until the CNC machine is done with designing and constructing its dies, the system is at an impasse. CNC machines eliminate considerable amounts of time in configuring and designing, shifting the focus to cutting, and the end result greatly increases the time taken to deliver the order. With CNC technology, the time taken to deliver an order has rapidly decreased, making it a preferred choice for numerous industries. In an era where the ability to work quickly is regarded as a skill, having the ability to work while using CNC machines also greatly helps to increase productivity.

Material Efficiency and Cost Savings

A problem that is present with all gasket-manufacturing techniques is the wasting of materials. With die cutting, on the other hand, the layouts are less efficient, thus increasing the rates of scrap material. Some CNC gasket cutting machines, however, may have advanced nesting, which is software that optimally places specific shapes on sheets of raw material. This, in turn, saves material and minimizes material waste, and can save the company a considerable amount of money in the long run. This is especially true for manufacturers that work with expensive materials, such as silicon, graphite, or PTFE. As long as there is a combination of reduced labor and tooling costs, CNC machines are guaranteed to have increased material savings, thus having a high ROI.

Consistency and Quality Assurance

Consistency is another area where CNC machines have the upper hand over traditional dies when high-volume production is concerned. In the case of gasket production, manual errors or mechanical dies suffering from wear and tear can create gasket quality issues. With CNC machines, there are no more issues of quality separation as the gaskets are cut from the same material, and each cut is digitally programmed. Regardless of whether it is a single prototype or thousands of identical gaskets, the quality is the same. Such gaskets help manufacturers not only fulfill the high standards required of them, but they can also make a name for themselves as someone with reliable products.

Conclusion

The adoption of CNC machines for gasket cutting is revolutionary for the industry. Rather than regarding it as a mere shift in technology, it is a shift in the paradigm of gasket manufacturing. Other traditional methods are inefficient in comparison to CNC technology’s even faster production with greater material customization, resulting in the industry’s new standard. Every business desires to minimize costs while speeding up production and improving consistency, and for them, CNC gasket cutting machines are the answer. These machines are taking the place of traditional dies.