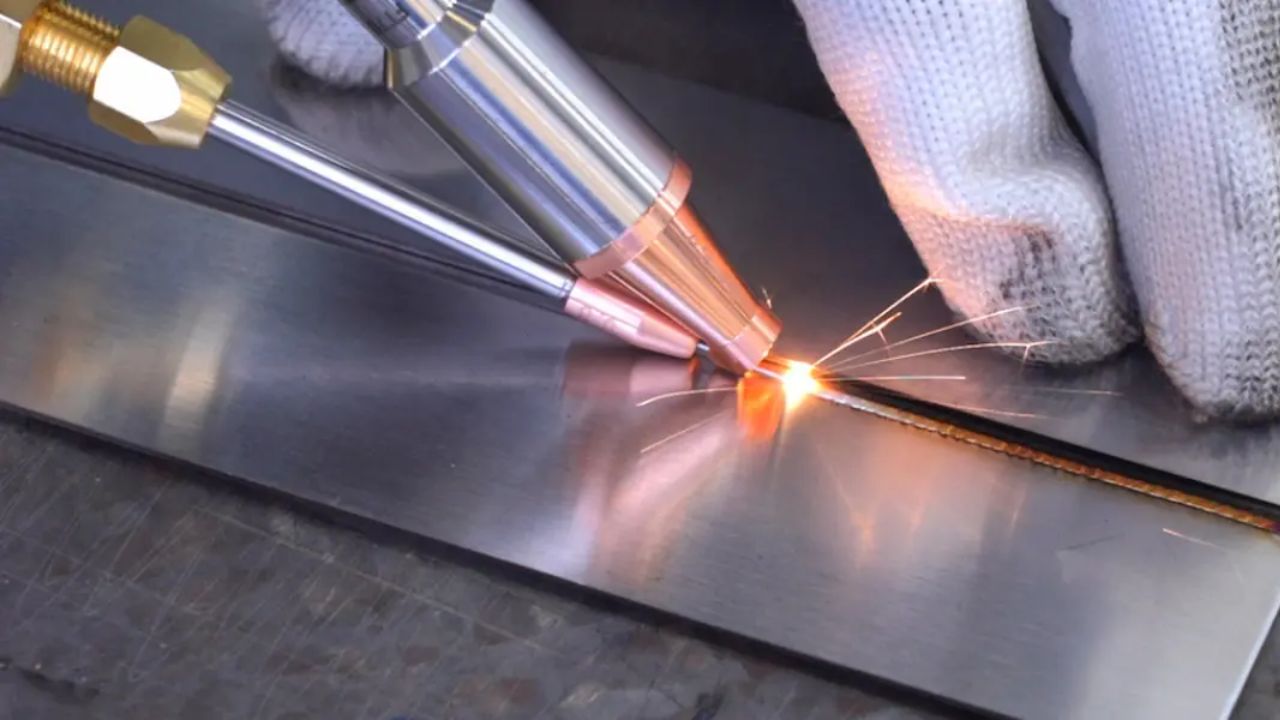

The modern manufacturing industry experiences rapid change, while laser welding technology leads this transformation. Businesses find laser welding machines increasingly appealing when they seek to improve their precision and speed, and efficiency. The decision-making process for laser welding machines is significantly influenced by price considerations. Businesses need to understand the key elements that determine laser welding machine prices when they want to invest strategically. The following are the five main elements that determine laser welding machine cost.

Laser Power and Source Technology

The price of laser welding machines depends heavily on two key elements: laser power strength and the laser source type selected by manufacturers. The wattage measurement of laser power determines how well the machine handles thick materials while achieving faster operation speeds. The price of the machine rises directly with its power output level. A 1000W laser welding machine costs less than a 3000W system intended for industrial usage because of its lower power capacity.

The price of laser welding machines depends heavily on the selection of laser source type between fiber laser, CO₂ laser and diode laser. The industry standard fiber lasers maintain higher prices than older technologies because they offer better efficiency and longer lifespan and require less maintenance. The latest fiber laser sources deliver superior machine performance yet demand elevated prices from their customers.

Precision, Beam Quality, and System Complexity

The price level increases when machines reach higher precision levels and produce better beam quality. State-of-the-art laser welding systems utilize sophisticated optical components and software programs to produce weld seams with high precision, along with minimal dimensional changes. Systems that need high-quality beam delivery with low beam parameter products (BPP) and excellent M² values lead to increased manufacturing expenses that result in elevated selling prices.

The complexity of systems causes expenses to increase. Machines that combine multi-axis CNC functionality with automated weld tracking and adaptive beam shaping capabilities extend their ability to perform complex welds on difficult materials or shapes. The implementation of extra features increases both engineering expenses and software development expenses and component costs, leading to higher prices for buyers.

Automation and Integration Features

Laser welding machines in modern production settings now provide multiple automated and integrated features to satisfy mass production needs. The addition of automated feeding systems, together with robotic arms and vision systems for real-time tracking and in-line quality inspection modules, drives up the price significantly above basic manual or semi-automatic systems.

Manufacturers who want to integrate laser welding machines into their existing production lines need to perform extensive customization and programming work, especially when operating in automotive manufacturing industries. The initial expenses grow due to custom interface development and control software creation, and system testing requirements. The initial purchase cost of these features increases substantially because they provide labor savings and faster production speeds, and improved quality.

Brand Reputation and After-Sales Support

The cost of a laser welding machine strongly depends on the brand name it carries. Products from reputable brands that maintain high standards of reliability and technological innovation, and after-sales service support, often command higher prices than unknown manufacturers. Customers are willing to spend extra money on equipment because they want assurance of reliable customer service, together with comprehensive warranties and immediate access to replacement parts.

The total cost rises because after-sales services, including on-site installation and operator training and regular maintenance packages, and quick-response repair services, enhance value. The investment in a reputable brand with a complete support system provides better value to companies focused on operational uptime and downtime reduction despite its initial cost premium.

Additional Features and Customization Options

The total price of a laser welding machine is significantly affected by the addition of special features and customization options. The price increases when buyers select welding heads with specialized functions and advanced cooling systems and integrated fume extraction units and proprietary weld design, and monitoring software. The additional features and enhancements increase both the machine’s complexity and its total cost.

The price increases when manufacturers require customized solutions to match their exclusive production needs, including material-specific adaptations and high-speed operations or non-typical production areas. Manufacturers need to spend time and money on developing custom solutions, which require testing and validation before the customer receives the bill.

Conclusion

The purchase of a laser welding machine demands a thorough evaluation of multiple expense components. The overall price of a laser welding machine depends on laser power capabilities, alongside system precision features and automation capabilities and brand reputation status, and customization capabilities. Businesses achieve optimal purchasing decisions through their understanding of key elements, which combine budget limitations with operational requirements to secure long-term productivity and profitability in competitive markets.