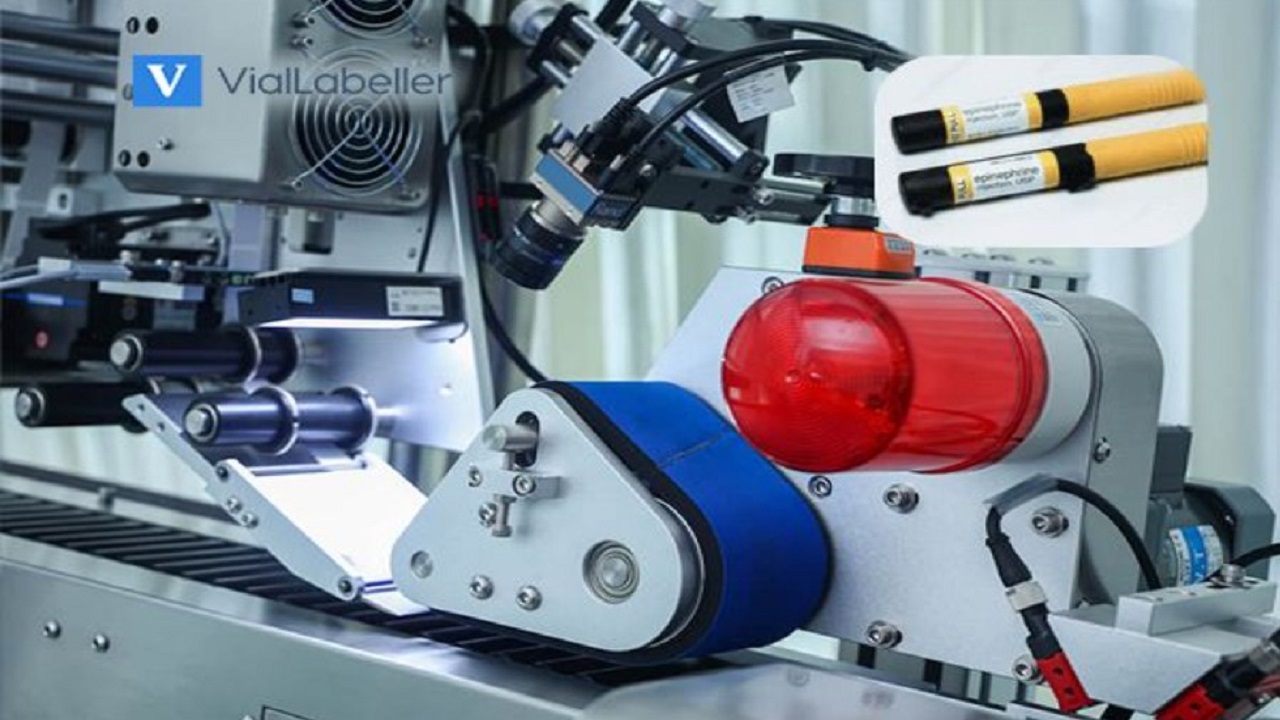

Labeling is an important element of the safety of drugs in the pharmaceutical packing environment. The vial labeler plays an important role in minimizing the dangers. These are the machines designed to affix labels to vials carrying pharmaceutical products precisely and consistently.

This article discusses how quality labeling machines can mitigate risks in pharmaceutical packaging worldwide and increase safety on a wider scale. A packaging error can lead to terrible consequences, such as providing the wrong medication.

Strengthen Traceability and Tracking

Pharmaceutical manufacturers must keep an eye on individual products for safety and regulatory reasons. Quality labeling machines also make products easily traceable in the supply chain. Unique application codes, or barcodes, are applied by the labeling machines that can be scanned at different points of the supply chain process, thus making it easy to track a product from production to distribution.

- Barcode Scanning: A machine prints and applies barcodes, which can then be scanned to authenticate the right product for shipping.

- Tracking Information: Labels trace batches during product recalls for rapid and accurate measures.

- Improved Inventory Management: Labels with tracking information enhance inventory control and the likelihood of an error in shipment.

Correct Information on the Label

The label on pharmaceutical packaging isn’t a sticker with the name of the medication because it tells the name of the drug, dosage, and legality. Poorly applied labels can cause serious injury, such as medication errors or misapplication. With the use of a vial labeler, no vial will be incorrectly labeled, minimizing the chances of mislabeling.

- Accurate Dosage: This machine helps apply labels that indicate the appropriate dosage, preventing confusion between patients and healthcare providers.

- Clear Instructions: Ensures that essential instructions on usage or storage are displayed clearly on the package.

- Conformity to Regulations: Standards for pharmaceutical products are rigid and well-defined. Labeling machines help manufacturers meet these standards by producing labels that can be read easily and consistently.

Reduce Human Error in the Labeling Process

Human error is considered one of the most significant risks in pharmaceutical packaging, as one misplaced or misaligned label may lead to severe consequences. Labeling machines like vial labelers can automate this process so that labels are always applied correctly.

Benefits of Automation in Labeling

- Speed and Efficiency: Labeling machines label quickly and speed up production with the highest level of accuracy.

- Consistency: It ensures placing every label in the same location and aligning it perfectly, thus avoiding mistakes in packaging.

- Reduced Fatigue: Machines are not like humans that become tired. Hence, mistakes are minimized, producing a reliable production line.

Lessen the risk of contamination

Cleanliness and contamination prevention are other important points to consider in pharmaceutical packaging. Quality labeling machines are designed for work environments controlled to minimize contamination. They also ensure a hygienic labeling process, avoiding the introduction of foreign particles or substances in the pack.

How Do Labeling Machines Prevent Contamination?

- Sealed Environments: Many labeling machines are built for sterile environments, preventing any external contaminants from affecting the products.

- Automated Process: An inefficient manual operation is replaced by automation, which lowers the chances of contamination during packaging.

Conclusion

The high-end labeling machines are an important consideration in minimizing risks in pharmaceutical packaging. Accurate labeling, minimized human error, enhanced traceability, and prevention of contamination are some of the fundamental ways that ensure the safety of a product for consumption.

Labeling machines serve very critical purposes by the pharmaceutical industry for meeting all regulatory standards required, protecting patients, and ensuring efficiency in production lines. With the increasing complexity of the pharmaceutical industry, the role of quality labeling machines will continue to grow in importance, providing critical support to manufacturers and ensuring public safety.